The following is a list of equipment and capabilities of our shop:

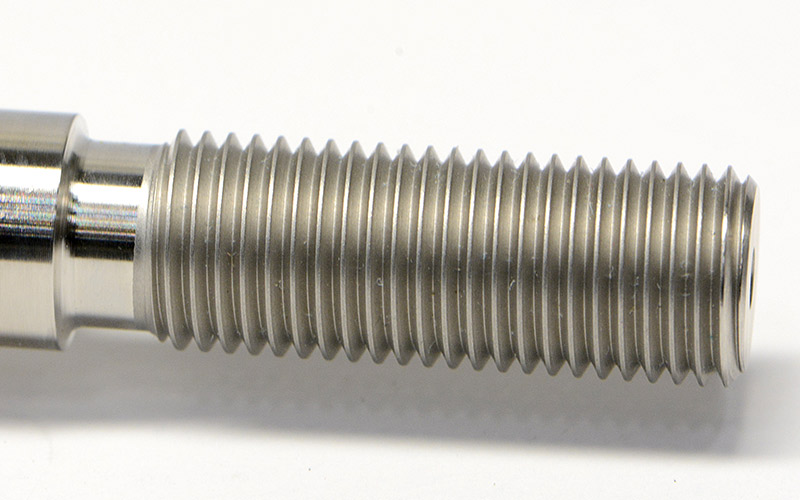

- State-of-the-Art turning centers capable of producing very tight tolerances

- Turn/ Mill parts 3/8” to 8” dia

- Milling, drilling, and tapping capability

- Water-based Coolant

- Many types of parts can be completed in 1 operation (Improving consistency and accuracy over parts going to a secondary operation)

- T32-3, 640T Fusion, and new Matrix2 Controls feature fast, capable programming

- Capto and WTO Hi Performance Live Tool attachments

CNC Machining Department

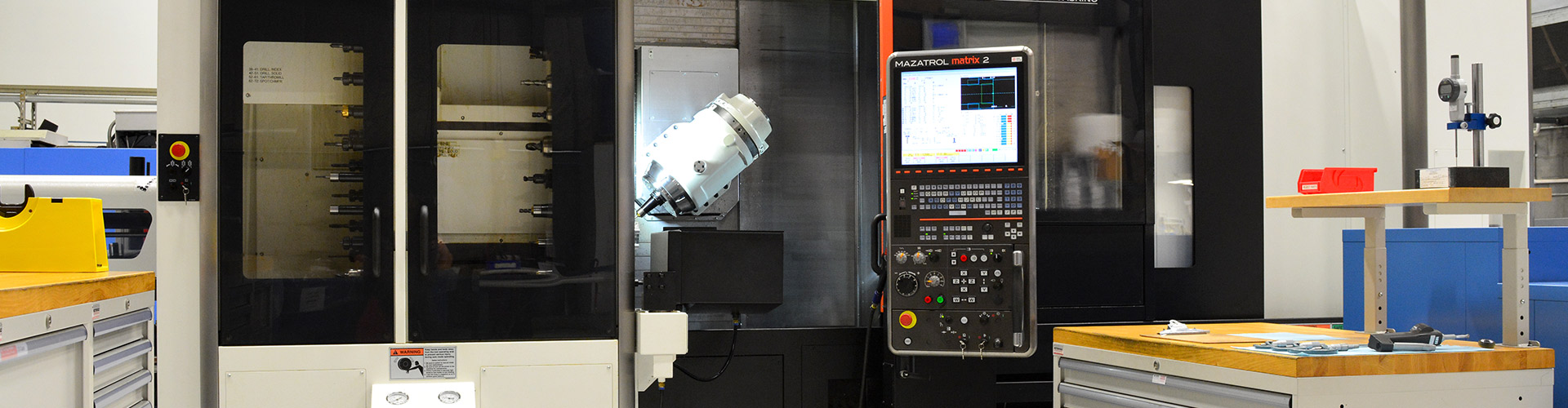

Mazak Integrex i200-ST Simultaneous 5 Axis CNC Machining Center

- Spindle Chiller

- Coolant Chiller

- Glass Feedback scales (improved accuracy over traditional encoder positioning feedback)

- 2-1/2″ Bar Thru Capacity with Bar Feeder

- 2 Opposing Turning Spindles – 8″ 3 Jaw Kitigawa Chucks. Producing first and second side machining in one operation.

- Twin Turrets – Machining w/ multiple tools simultaneously.

- Upper Turret: Articulating 30HP, 12000 RPM Milling Spindle/Turning Turret. 72 Tools, 1000psi Thru Head Coolant

- Features Capto spindle couple – most rigid tool holding coupling in the industry.

- Lower Turret: 9 Turning Tool Capacity

- Matrix2 Mazatrol/ EIA/ISO control

- Capable of +/-.0002 tolerances on many features

- Typical Part Size: 1/2″ to 8″ dia.

- Full Milling, Drilling, Tapping capability on an plane, including simultaneous 5-axis machining.

- C-Axis – Rotational (360 deg Position/Feeding) on both Turning Spindles (Indexing Chucks)

- B-Axis – “Tilt” Axis for the Upper Turret – Making machined features on any Plane Angle possible.

- Y-Axis – Milling/ Positioning Off Centerline (horizontal & vertical)

- W-Axis – Subspindle Transfer and Positioning

- 1000 PSI Coolant, Parts Conveyor

(2) Mazak Nexus QTN250MSY 5 Axis CNC Turning Center

- Coolant Chiller

- Glass Feedback scales (improved accuracy over traditional encoder positioning feedback)

- 3″ Bar Thru Capacity

- 10″ 3 Jaw Kitigawa Chuck – Main side

- 6″ 3 Jaw Kitigawa Chuck – Sub Side. Producing first and second side machining in one operation.

- 12 Position Turret (Live or Static)

- Matrix Mazatrol/ EIA/ISO control

- Capable of +/-.0002 tolerances on many features

- Typical Parts diameters: 3/8″ to 8″ dia.

- Horizontal/Vertical Milling, drilling, tapping capability

- C-Axis – Rotational (360 deg Position/Feeding)

- Y-Axis – Milling/ Positioning Off Centerline (horizontal & vertical)

- B-Axis – Subspindle Transfer and Positioning

- 1000 PSI Coolant, Parts Conveyor

Mazak SQT200MSY 5 Axis CNC Turning Center

- 2″ Bar Thru Capacity

- 8″ 3 Jaw Kitigawa Chuck – Main side

- 22J Collet Chuck (Dead Length, 2-1/4″ Cap) – Sub Side. Producing first and second side machining in one operation.

- 12 Position Turret (Live or Static)

- 640T Fusion Mazatrol/ EIA/ISO control

- Capable of +/-.0002 tolerances on most features

- Typical Parts diameters: 3/8″ to 6″ dia.

- Horizontal/Vertical Milling, drilling, tapping capability

- C-Axis – Rotational (360 deg Position/Feeding)

- Y-Axis – Milling/ Positioning Off Centerline (horizontal & vertical)

- B-Axis – Subspindle Transfer and Positioning

Mazak SQT200MS 4 Axis CNC Turning Center

- 2″ Bar Thru Capacity

- 8″ 3 Jaw Kitigawa Chuck – Main side

- 22J Collet Chuck (Dead Length, 2-1/4″ Cap) – Sub Side. Producing first and second side machining in one operation.

- 12 Position Turret (Live or Static)

- 640T Fusion Mazatrol/ EIA/ISO control

- Capable of +/-.0002 tolerances on most features

- Typical Parts diameters: 3/8″ to 6″ dia.

- Horizontal/Vertical Milling, drilling, tapping capability

- C-Axis – Rotational (360 deg Position/Feeding)

- B-Axis – Subspindle Transfer and Positioning

Mazak QT200Y 3 Axis CNC Turning Center

- 2-1/2″ Bar Thru Capacity

- 8″ 3 Jaw Schunk Chuck

- Programmable Tailstock & Live Center for shaft type work

- 12 Position Turret (Live or Static)

- Smooth G control

- Capable of +/-.0003 tolerances on most features

- Typical Parts diameters: ½ ” to 6″ dia.

- Horizontal/Vertical Milling, drilling, tapping capability

- C-Axis – Rotational (360 deg Position/Feeding)

Dake Horizontal Automatic Bandsaw

- 10″ Capacity

- Minimum Material Remnants

- Metal alloys and Plastics

- Consistent and Square Cuts

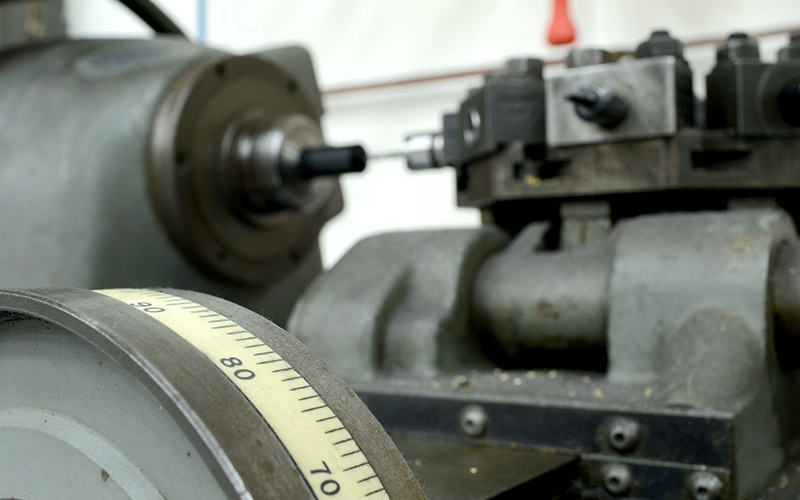

Hardinge Precision Manual Lathe

- Making tooling/fixturing for shop use

Bridgeport, 3 Axis Mill

- Making tooling/fixturing for shop use

- Newall 3 axis DRO

Inspection Department

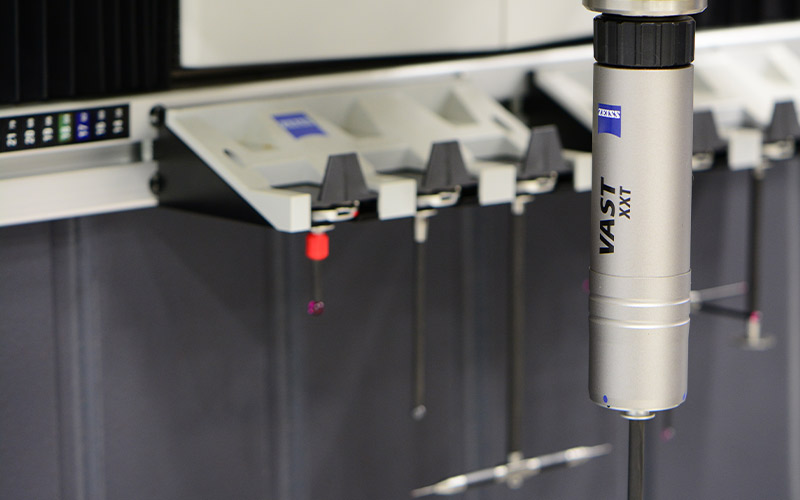

Zeiss Duramax CMM

- VAST XXT Scanning Sensor

- Calypso Simulation Software

- E0/E40 in µm MPE according to ISO 10360-2:2009

- 500mm x 500mm x 500mm

- Complete Laser Arsenal Component Fixturing System

Mitutoyo PH-3500 Optical Comparator

- 14″ Screen, 10x lenses

- Quadra Check 200 measuring electronics (used to measure complex features)

- Electronic Edge Detection

- Customized w/ Fiber-Lite MI-150 Illuminator (improved surface illumination)

- Annual Calibration traceable to NIST

Mitutoyo QM 600 Height Gage

- Measuring large parts and distances between feature

- 24″ Measuring Capability

- +/-.0001 Accuracy

- Special Carbide tip assortment for difficult to measure features

- Annual Calibration traceable to NIST

Mitutoyo Borematic 568 Digimatic Bore Gages

- Range: 0.2750 – 4.0000″

- Resolution: .00005″/0.001mm

- Accuracy: .00020

Mitutoyo ID-C Digimatic Indicator (543-492B)

- At every work center

- Range: 0 – 2.000″

- Resolution: .00005″/0.001mm

- Accuracy: .00020

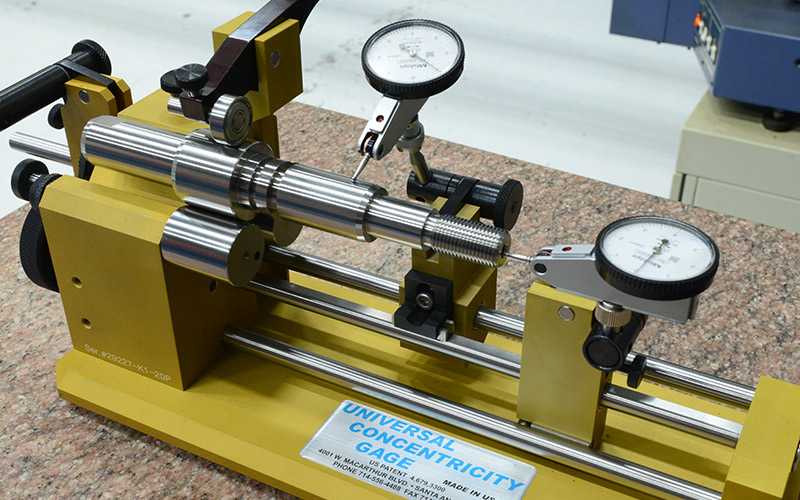

Universal Punch K1-20 Precision Concentricity Gage

- Diameter Capacity: 3/8″ to 2″ (10mm to 50mm)

- Length Capacity: ≤ 6″ (152mm)

- Precision Accuracy: ≤ 2µm (.00008″)

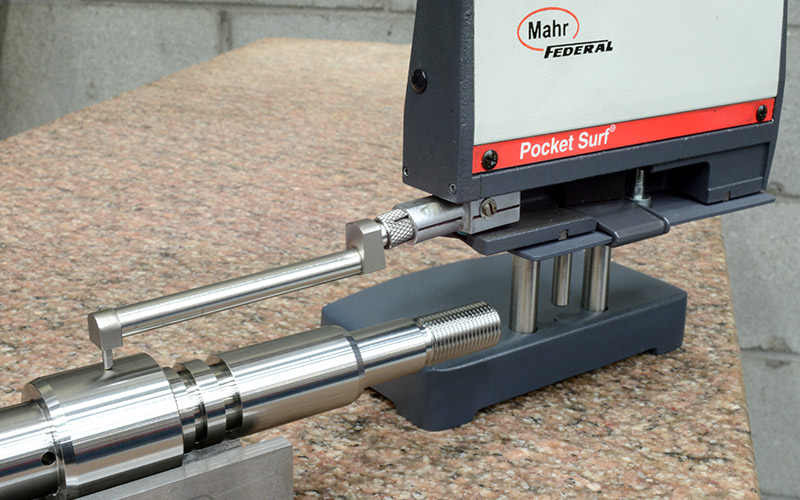

(4) MAHR-Federal Profilometer

- Measures surface finish Ra, Rmax/Ry, Rt

- ANSI-B46, ISO and MIL specifications

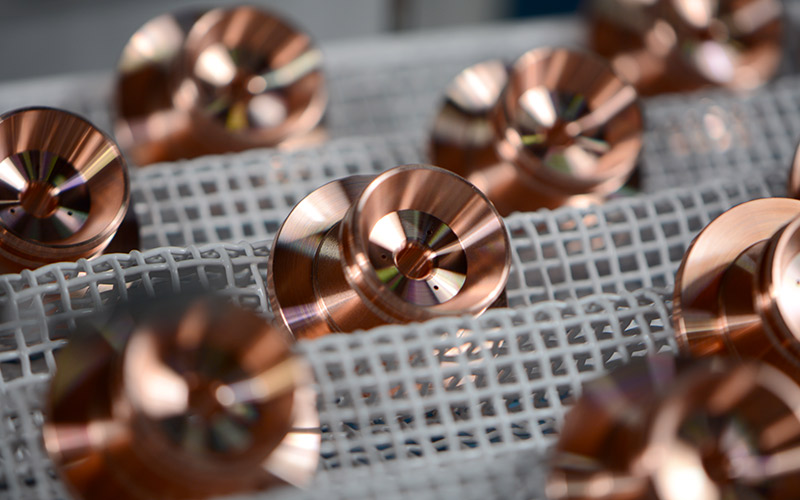

Finishing Department

Overbeck High Speed Polishing Lathe – Model LT-1B

- 2600 RPM Polishing Lathe

- Operator uses various media pads to achieve finishes as low as 2Ra

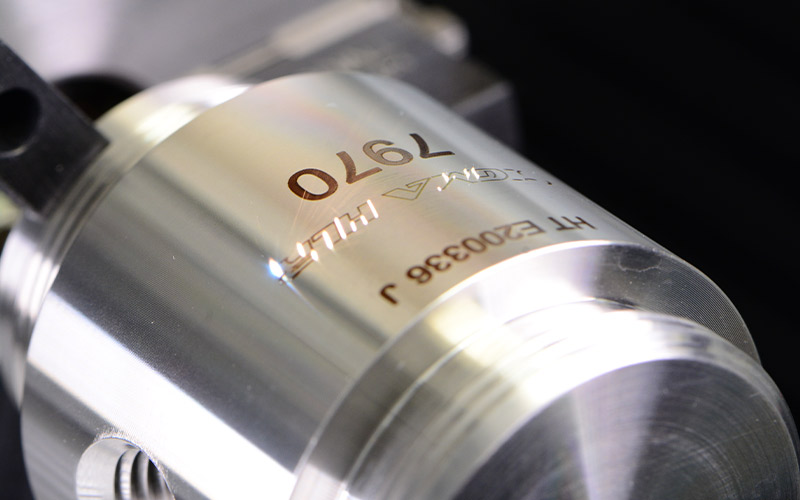

Trumpf Trumark 5000 Laser Marker

- Reliable and Precise Marking

- Diode-pumped Fiber Laser (Yb-fiber)

- X/Y programmable work table (300mm x 300mm)

- Programmable Z axis focal distance

- Programmable Rotary Indexer

- Clean, Consistent Marker on Variety of Materials

- Complete Laser Arsenal Component Fixturing System

Dapra Technomark Multi4

- Alpha-numeric marking

- Programmable character size

- Discrete dot marking or continuous line fonts

- Marking at angles, circular, straight line, mirror and italic marking

- Serial Number module

Branson Ultrasonic Cleaners

- Removes contaminants from machine operations

- Cleans parts brilliantly

UNI-POL 8″ Lapping Machine

- Lap parts face to small flatness requirements

Baldor 8” Buffer/Polisher

- Creating uniform edge breaks

- Polish to mirror finishes

Cyclone 36” Bead Blast Cabinet

- Trinco Med/Fine Glass Bead (applying light blasted finishes)

- 100 Grit Black Silicone Grit (medium/aggressive deburring)