Mazak Integrex i200-ST Simultaneous 5 Axis CNC Machining Center

- Spindle Chiller

- Coolant Chiller

- Glass Feedback scales (improved accuracy over traditional encoder positioning feedback)

- 2-1/2″ Bar Thru Capacity with Bar Feeder

- 2 Opposing Turning Spindles – 8″ 3 Jaw Kitigawa Chucks. Producing first and second side machining in one operation.

- Twin Turrets – Machining w/ multiple tools simultaneously.

- Upper Turret: Articulating 30HP, 12000 RPM Milling Spindle/Turning Turret. 72 Tools, 1000psi Thru Head Coolant

- Features Capto spindle couple – most rigid tool holding coupling in the industry.

- Lower Turret: 9 Turning Tool Capacity

- Matrix2 Mazatrol/ EIA/ISO control

- Capable of +/-.0002 tolerances on many features

- Typical Part Size: 1/2″ to 8″ dia.

- Full Milling, Drilling, Tapping capability on an plane, including simultaneous 5-axis machining.

- C-Axis – Rotational (360 deg Position/Feeding) on both Turning Spindles (Indexing Chucks)

- B-Axis – “Tilt” Axis for the Upper Turret – Making machined features on any Plane Angle possible.

- Y-Axis – Milling/ Positioning Off Centerline (horizontal & vertical)

- W-Axis – Subspindle Transfer and Positioning

- 1000 PSI Coolant, Parts Conveyor

(2) Mazak Nexus QTN250MSY 5 Axis CNC Turning Center

- Coolant Chiller

- Glass Feedback scales (improved accuracy over traditional encoder positioning feedback)

- 3″ Bar Thru Capacity

- 10″ 3 Jaw Kitigawa Chuck – Main side

- 6″ 3 Jaw Kitigawa Chuck – Sub Side. Producing first and second side machining in one operation.

- 12 Position Turret (Live or Static)

- Matrix Mazatrol/ EIA/ISO control

- Capable of +/-.0002 tolerances on many features

- Typical Parts diameters: 3/8″ to 8″ dia.

- Horizontal/Vertical Milling, drilling, tapping capability

- C-Axis – Rotational (360 deg Position/Feeding)

- Y-Axis – Milling/ Positioning Off Centerline (horizontal & vertical)

- B-Axis – Subspindle Transfer and Positioning

- 1000 PSI Coolant, Parts Conveyor

Mazak SQT200MSY 5 Axis CNC Turning Center

- 2″ Bar Thru Capacity

- 8″ 3 Jaw Kitigawa Chuck – Main side

- 22J Collet Chuck (Dead Length, 2-1/4″ Cap) – Sub Side. Producing first and second side machining in one operation.

- 12 Position Turret (Live or Static)

- 640T Fusion Mazatrol/ EIA/ISO control

- Capable of +/-.0002 tolerances on most features

- Typical Parts diameters: 3/8″ to 6″ dia.

- Horizontal/Vertical Milling, drilling, tapping capability

- C-Axis – Rotational (360 deg Position/Feeding)

- Y-Axis – Milling/ Positioning Off Centerline (horizontal & vertical)

- B-Axis – Subspindle Transfer and Positioning

Mazak SQT200MS 4 Axis CNC Turning Center

- 2″ Bar Thru Capacity

- 8″ 3 Jaw Kitigawa Chuck – Main side

- 22J Collet Chuck (Dead Length, 2-1/4″ Cap) – Sub Side. Producing first and second side machining in one operation.

- 12 Position Turret (Live or Static)

- 640T Fusion Mazatrol/ EIA/ISO control

- Capable of +/-.0002 tolerances on most features

- Typical Parts diameters: 3/8″ to 6″ dia.

- Horizontal/Vertical Milling, drilling, tapping capability

- C-Axis – Rotational (360 deg Position/Feeding)

- B-Axis – Subspindle Transfer and Positioning

Mazak QT200Y 3 Axis CNC Turning Center

- 2-1/2″ Bar Thru Capacity

- 8″ 3 Jaw Schunk Chuck

- Programmable Tailstock & Live Center for shaft type work

- 12 Position Turret (Live or Static)

- Smooth G control

- Capable of +/-.0003 tolerances on most features

- Typical Parts diameters: ½ ” to 6″ dia.

- Horizontal/Vertical Milling, drilling, tapping capability

- C-Axis – Rotational (360 deg Position/Feeding)

Dake Horizontal Automatic Bandsaw

- 10″ Capacity

- Minimum Material Remnants

- Metal alloys and Plastics

- Consistent and Square Cuts

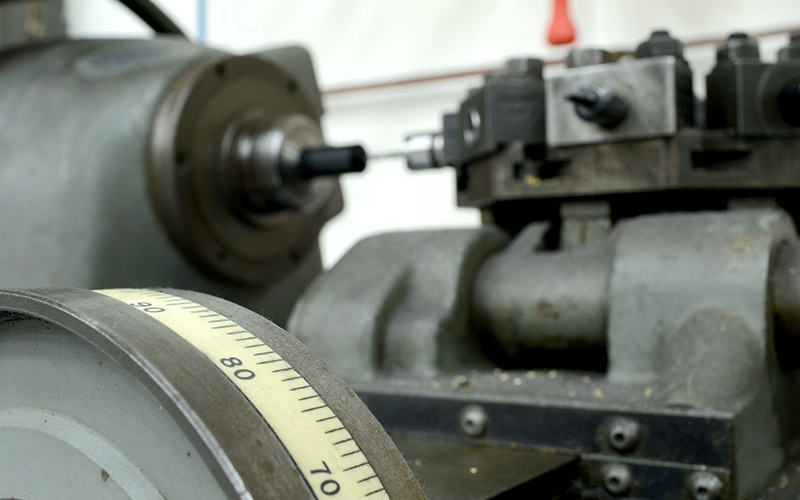

Hardinge Precision Manual Lathe

- Making tooling/fixturing for shop use